JZ Series

The HXHJ-JZ Series Workshop Dust Extractor is specially developed for smoke and dust removal in large-scale workpiece production workshops. It provides a reliable solution for capturing and filtering welding fume, cutting smoke, grinding dust, and polishing particles.

Send Inquiry

| Air volume | 10000-15000m³/h |

| Appearance | Modular design |

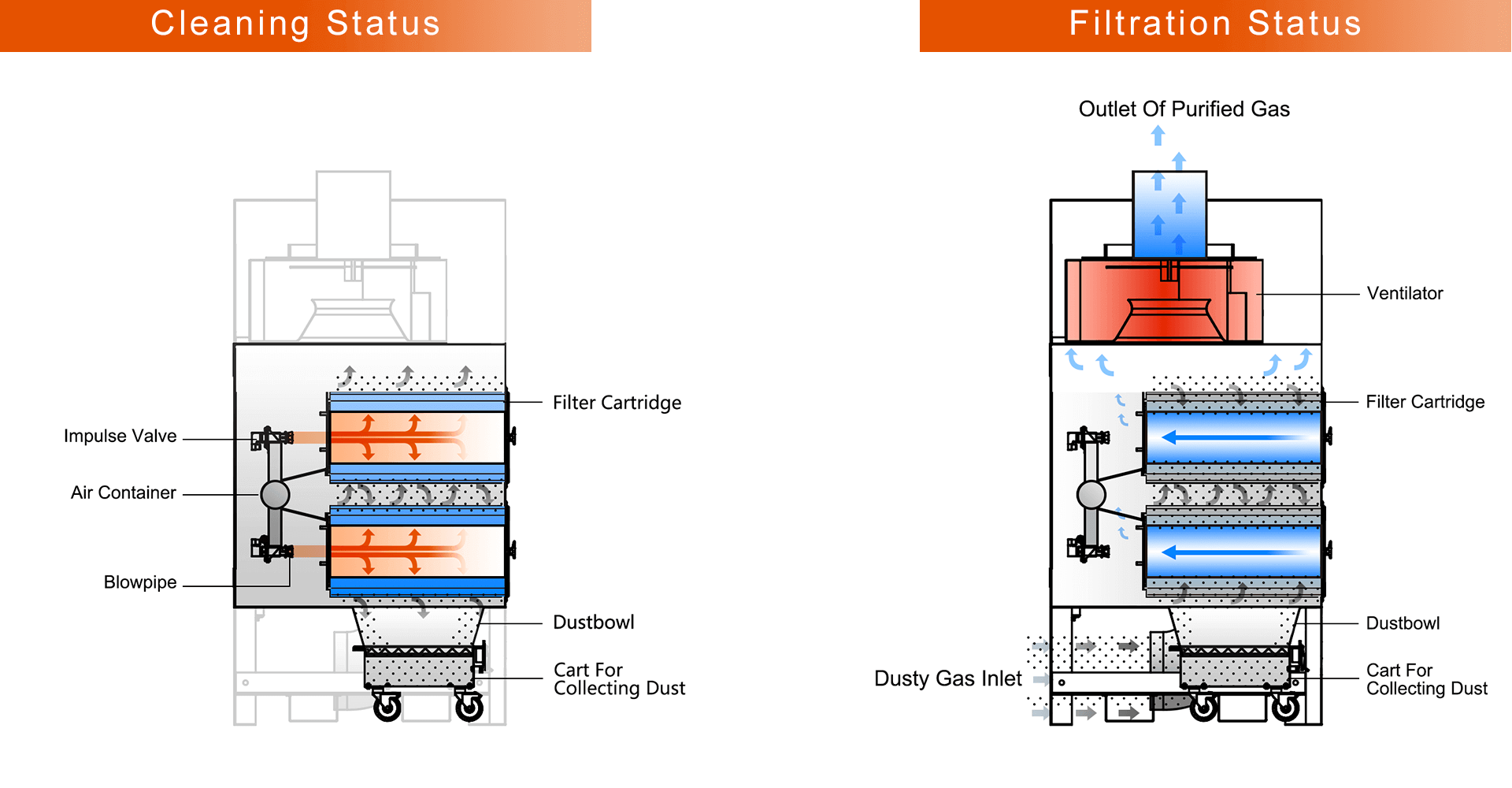

| Cleaning method | Venturi pulse cleaning |

| Dust removal efficiency | 99.99% |

| Filter cartridge installation method | Horizontal mounting |

| breaker | Schneider |

| PLC control system touch screen | Siemens |

| Product Model | HXYD-JZ08 | HXYD-JZ16 | HXYD-JZ24 | HXYD-JZ32 | HXYD-JZ40 | HXYD-JZ48 | HXYD-JZ56 | HXYD-JZ64 | HXYD-JZ72 | HXYD-JZ80 |

| Handling air volume | 10000-15000m³/h | 20000-30000m³/h | 30000-45000m³/h | 40000-60000m³/h | 50000-75000m³/h | 60000-90000m³/h | 70000-105000m³/h | 80000-120000m³/h | 90000-135000m³/h | 100000-150000m³/h |

| Filtration area | 144㎡ | 288㎡ | 432㎡ | 576㎡ | 720㎡ | 864㎡ | 1008㎡ | 1152㎡ | 1296㎡ | 1440㎡ |

| Number of filter cartridges | 8 | 16 | 24 | 32 | 40 | 48 | 56 | 64 | 72 | 80 |

| Filter cartridge installation method | Horizontal | |||||||||

| Filter cartridge specifications | Φ325*L1000mm | |||||||||

| Filter cartridge material | Polyester fiber + PTFE coating | |||||||||

| Filter cartridge brand | Jinan Huaxin | |||||||||

| Filtration efficiency | 99.99% | |||||||||

| Filtration accuracy | 0.3μm | |||||||||

| Cleaning method | Fully automatic Venturi cleaning | |||||||||

| Air bag material | 304 stainless steel | |||||||||

| Compressed air | 0.4-0.6Mpa | |||||||||

| Air inlet size (air inlet distance from the ground) |

φ500mm (690mm) |

|||||||||

| Dust collection device | Special dust collection trolley | |||||||||

| Equipment dimensions (length*width*height) |

1*1.5*2.9 (m) | 1.8*1.5*2.9 (m) | 2.8*1.5*2.9 (m) | 3.8*1.5*2.9 (m) | 4.8*1.5*2.9 (m) | 5.8*1.5*2.9 (m) | 6.8*1.5*2.9 (m) | 7.8*1.5*2.9 (m) | 8.8*1.5*2.9 (m) | 9.8*1.5*2.9 (m) |

| Machine weight | 500±10Kg | 1000±10Kg | 1500±10Kg | 2000±10Kg | 2500±10Kg | 3000±10Kg | 3500±10Kg | 4000±10Kg | 4500±10Kg | 5000±10Kg |

JZ adopts vertically installed quick-release filter elements, which facilitate the disassembly and maintenance of the filter elements.

Modular design, compact structure, small footprint, easy to transport and install.

The cleaning method can be selected from rotor pulse cleaning or Venturi pulse cleaning.

The dust removal equipment has added a delayed cleaning function. After the main fan stops working, it continues to maintain pulse cleaning for a period of time to extend the service life of the filter cartridge.

The power core A-type centrifugal fan is built-in design, and the fan blades and wheel cover are molded and molded. it has the advantages of energy saving, high efficiency, low noise, and stable performance.

The vertically mounted quick-loading filter element is used to facilitate the dis assembly and maintenance of the filter element. The filter element uses im ported high-efficiency flame-retardant film-coated filter material. with a filtra tion accuracy of up to 99.99%, and the filtered clean gas can be effectively cir- culated.

Through repeated impact vibrations with small amplitude, the dust accumulat- ed on the outside of the filter cartridge is shaken into the ash hopper.

The ash hopper is equipped with a multi-shaped anti-ash return device and an ash level meter to provide real-time feedback on the amount of dust accumu lated in the ash hopper, prompting dust cleaning, and extending the service life of the equipment.

Easy to operate,simple dust cleaning method, large capacity

Jinan Huaxin Automation Engineering Co., Ltd. is the only national high-tech enterprise in China dedicated to providing overall solutions for the entire industrial chain of process gas systems and waste gas treatment systems. It is a professional manufacturer in the field of industrial environmental protection and dust removal.

Meet national health and safety production standards, with a particle concentration of less than 4 milligrams in the production environment

The filter element has a service life of about 5000 hours, and the replacement cycle is 6-12 months depending on the working conditions.

Adjust the appropriate pulse frequency according to production conditions, regularly clean the dust in the ash hopper, and have trained personnel operate the equipment

ISO,CE, SGS

Jinan Huaxin's products are exported to more than 100 countries and regions around the world, mainly including the United States, Canada, Mexico, Germany, France, the Netherlands, Italy, Spain, Portugal, Hungary, Romania, Russia, Ukraine, Australia, New Zealand, Argentina, Chile, Thailand, Vietnam, the Philippines, etc

The nano filter has a large filtration area and flame retardant effect, and the filter cartridge material will not burn when the open flame is extinguished

End user; Shanghai Zhenhua, COSCO Shipping, China Merchants Heavy Industry, Sany Heavy Industry, Lingong, XCMG, Liugong, Longgong, Beijing Coal Machinery, Zhengzhou Coal Machinery, Hancheng Coal Machinery, Pingdingshan Coal Machinery, China National Heavy Duty Truck Group, Shaanxi Automobile Group, Dongfeng Motor, BYD, Geely Automobile, Chery Automobile and more than 3000 end users, laser matching; Over 50 laser manufacturers, including Bodor Laser, HSG Laser, Jinweike Laser, Red Bull Laser, Longdiao Laser, Xintian Laser, Jinqiang Laser, etc., provide year-round export support for robot welding integration; More than 50 robot workstations, including Kunshan Huaheng, Xiamen Sirte, Tangshan Kaiyuan, Shanghai Hailike, Nanjing Estun, Nanjing Aote, Nanjing Hexin, Shandong Maihe, etc., are equipped with dust removal systems throughout the year

High operational stability under the same working conditions, high usage rate in the same industry, energy-saving and consumption reducing, low noise, small space occupation, exquisite appearance,

The size of the workpiece, working hours, specifications and dosage of the welding wire,

The filter cartridge has a service life and belongs to consumables

Purification of smoke and dust generated during welding and cutting conditions, collection and treatment of dust generated during polishing and laser rust removal, and treatment of exhaust gas odors in painting workshops,

Can meet the customized needs of customers