Health and safety in welding operations

Exhibition

2024-12-02 13:05:26

1. Hazards of welding smoke

During welding, metal materials evaporate under high temperature to form fine particles, which are suspended in the air to form welding smoke. Depending on the materials used, welding smoke may contain a variety of harmful substances, such as iron oxide, manganese and its compounds, heavy metal elements such as zinc, and harmful gases such as carbon monoxide and nitrogen oxides. Long-term inhalation of these pollutants can lead to respiratory diseases, nervous system damage, and even cancer.

2. Regulatory requirements

In order to protect the health rights and interests of workers, many countries and regions have formulated strict laws and regulations to limit the concentration of harmful substances in the air in the workplace. For example, the Occupational Safety and Health Administration (OSHA) in the United States has set occupational exposure limits for specific chemicals; the European Union has also passed relevant directives to protect workers from harmful environments. Complying with these regulations not only helps avoid legal risks, but also demonstrates corporate social responsibility.

3. Improve work efficiency

Good ventilation conditions can significantly improve the working environment and reduce discomfort or illness caused by pollution, thereby improving employee work enthusiasm and productivity. In addition, proper air purification measures can also help extend the service life of equipment and reduce maintenance costs.

4. Choose a suitable dust removal system

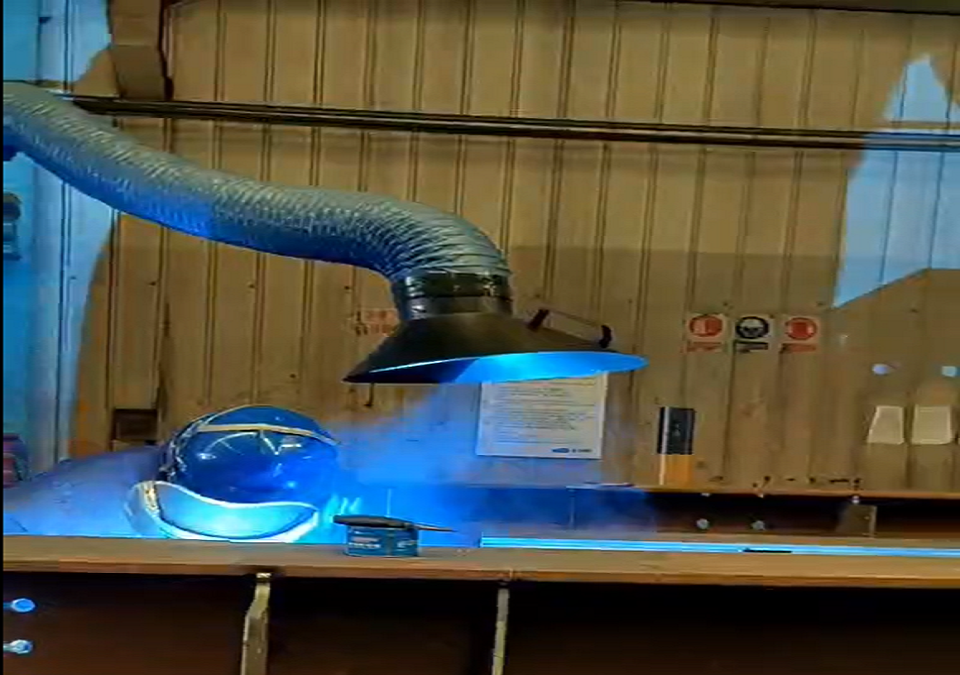

Local exhaust: For welding operations in fixed positions, installing a local exhaust device is the most direct and effective method. This system quickly exhausts the smoke in the welding area through the suction port.

Mobile dust collector: Suitable for welding tasks with strong mobility. This type of equipment is usually small in size, easy to carry, and suitable for use in different occasions.

Central dust collection system: When multiple welding machines are working at the same time in a large factory or workshop, it is more economical and efficient to use a central dust collection system. It can cover a wider area and is easy to manage and maintain.

5. Maintenance and care

Regular inspection and cleaning of filters and replacement of consumables are key steps to ensure dust removal effects. In addition, it is equally important to train employees to use dust removal equipment correctly. Only when everyone recognizes its importance and actively participates in it can the goal of safe production be truly achieved.

In short, equipping welding machines with appropriate dust removal facilities is not only a requirement to comply with laws and regulations, but also an important measure to reflect the company's care for employees. By taking effective protective measures, not only can a healthier and safer working environment be created, but also the overall operational efficiency can be improved, laying a solid foundation for the long-term development of the company.

If you need our help with the environment, please contact:

Missy

sales Manager

Email: missy@jnhxgm.com

Phone/WhatsApp/Wechat: (86)19861852197

During welding, metal materials evaporate under high temperature to form fine particles, which are suspended in the air to form welding smoke. Depending on the materials used, welding smoke may contain a variety of harmful substances, such as iron oxide, manganese and its compounds, heavy metal elements such as zinc, and harmful gases such as carbon monoxide and nitrogen oxides. Long-term inhalation of these pollutants can lead to respiratory diseases, nervous system damage, and even cancer.

2. Regulatory requirements

In order to protect the health rights and interests of workers, many countries and regions have formulated strict laws and regulations to limit the concentration of harmful substances in the air in the workplace. For example, the Occupational Safety and Health Administration (OSHA) in the United States has set occupational exposure limits for specific chemicals; the European Union has also passed relevant directives to protect workers from harmful environments. Complying with these regulations not only helps avoid legal risks, but also demonstrates corporate social responsibility.

3. Improve work efficiency

Good ventilation conditions can significantly improve the working environment and reduce discomfort or illness caused by pollution, thereby improving employee work enthusiasm and productivity. In addition, proper air purification measures can also help extend the service life of equipment and reduce maintenance costs.

4. Choose a suitable dust removal system

Local exhaust: For welding operations in fixed positions, installing a local exhaust device is the most direct and effective method. This system quickly exhausts the smoke in the welding area through the suction port.

Mobile dust collector: Suitable for welding tasks with strong mobility. This type of equipment is usually small in size, easy to carry, and suitable for use in different occasions.

Central dust collection system: When multiple welding machines are working at the same time in a large factory or workshop, it is more economical and efficient to use a central dust collection system. It can cover a wider area and is easy to manage and maintain.

5. Maintenance and care

Regular inspection and cleaning of filters and replacement of consumables are key steps to ensure dust removal effects. In addition, it is equally important to train employees to use dust removal equipment correctly. Only when everyone recognizes its importance and actively participates in it can the goal of safe production be truly achieved.

In short, equipping welding machines with appropriate dust removal facilities is not only a requirement to comply with laws and regulations, but also an important measure to reflect the company's care for employees. By taking effective protective measures, not only can a healthier and safer working environment be created, but also the overall operational efficiency can be improved, laying a solid foundation for the long-term development of the company.

If you need our help with the environment, please contact:

Missy

sales Manager

Email: missy@jnhxgm.com

Phone/WhatsApp/Wechat: (86)19861852197