Small pulse filter cartridge dust collector

Corporate News

2024-11-15 16:26:14

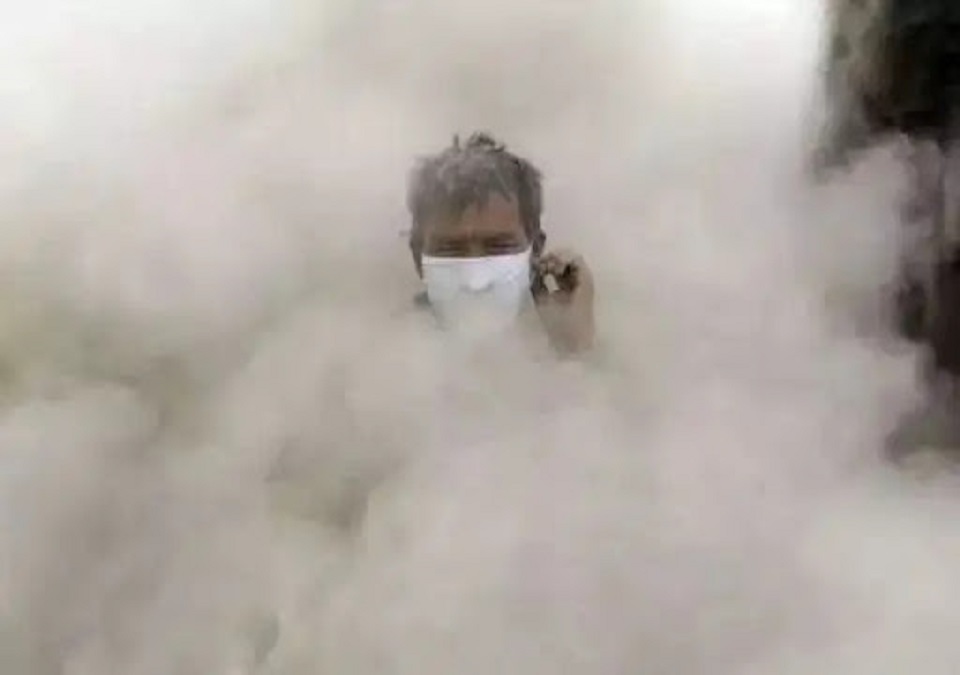

In modern industrial production, environmental protection and clean production have become an important part of the sustainable development of enterprises. As an efficient and energy-saving dust removal equipment, small pulse filter cartridge dust collector is widely used in dust control in various industries. This article will elaborate on the small pulse filter cartridge dust collector in detail from the aspects of working principle, structural characteristics, application field, performance advantages, operation and maintenance, and future development.

1. Working principle

The working principle of the small pulse filter cartridge dust collector is to use pulse blowing technology to instantly blow the filter cartridge through high-pressure gas to remove the dust on the surface of the filter cartridge, so that the filter cartridge remains clean, thereby ensuring the normal operation of the dust collector. During the dust removal process, the dust-containing gas enters the dust collector through the air inlet. After the filtering action of the filter cartridge, the dust is intercepted on the surface of the filter cartridge, and the clean gas is discharged through the air outlet.

2. Structural characteristics

The small pulse filter cartridge dust collector has the characteristics of compact structure, small footprint, and easy installation. Its filter cartridge is made of high-quality filter material, with good filtering performance and long service life. At the same time, the dust collector is also equipped with key components such as pulse jet system and control system, which realizes automatic control and reduces the cost of manual operation.

3. Application field

Small pulse filter cartridge dust collector is widely used in dust control in metallurgy, chemical industry, building materials, machinery, power and other industries. For example, in the cement production process, the dust generated by equipment such as grinding mills and packaging machines can be effectively treated by small pulse filter cartridge dust collectors; in metal processing processes such as welding and cutting, the smoke generated can also be purified by this equipment.

4. Performance advantages

(1) High-efficiency dust removal: Small pulse filter cartridge dust collector has a high dust removal efficiency and can intercept micron-level dust to ensure the cleanliness of exhaust gas.

(2) Energy saving and environmental protection: The equipment adopts pulse jet technology, which has good dust cleaning effect, low energy consumption and meets environmental protection requirements.

(3) Strong stability: The dust collector is made of high-quality materials and advanced technology, has high stability and reliability, and can operate stably for a long time.

(4) Easy maintenance: The equipment has a simple structure and is easy to maintain, which reduces the maintenance cost of the enterprise.

5. Operation and Maintenance

When operating a small pulse filter cartridge dust collector, pay attention to the following points:

(1) Check the cleanliness of the filter cartridge regularly. If the filter cartridge is found to be blocked or damaged, it should be replaced in time.

(2) Maintain the normal working state of the pulse injection system and regularly check parameters such as air source pressure and injection frequency.

(3) Clean and maintain the dust collector regularly, including cleaning the ash hopper, checking seals, tightening bolts, etc.

(4) Strictly abide by operating procedures and safety precautions to ensure the safe operation of the equipment.

6. Future Development

With the continuous improvement of environmental protection requirements and the development of industrial production, small pulse filter cartridge dust collectors will face more challenges and opportunities. In the future, the equipment will develop in a more efficient, energy-saving and intelligent direction. For example, by introducing advanced sensor technology and Internet of Things technology, remote monitoring and intelligent control of dust collectors can be realized; by optimizing filter materials and structural design, the filtering performance and stability of dust collectors can be improved; by developing new cleaning technologies, energy consumption and emissions can be reduced.

In short, as a highly efficient and energy-saving dust removal equipment, the small pulse filter cartridge dust collector plays an important role in industrial production. With the continuous advancement of technology and the continuous expansion of application fields, this equipment will show a broader market prospect and development potential in the future.

1. Working principle

The working principle of the small pulse filter cartridge dust collector is to use pulse blowing technology to instantly blow the filter cartridge through high-pressure gas to remove the dust on the surface of the filter cartridge, so that the filter cartridge remains clean, thereby ensuring the normal operation of the dust collector. During the dust removal process, the dust-containing gas enters the dust collector through the air inlet. After the filtering action of the filter cartridge, the dust is intercepted on the surface of the filter cartridge, and the clean gas is discharged through the air outlet.

2. Structural characteristics

The small pulse filter cartridge dust collector has the characteristics of compact structure, small footprint, and easy installation. Its filter cartridge is made of high-quality filter material, with good filtering performance and long service life. At the same time, the dust collector is also equipped with key components such as pulse jet system and control system, which realizes automatic control and reduces the cost of manual operation.

3. Application field

Small pulse filter cartridge dust collector is widely used in dust control in metallurgy, chemical industry, building materials, machinery, power and other industries. For example, in the cement production process, the dust generated by equipment such as grinding mills and packaging machines can be effectively treated by small pulse filter cartridge dust collectors; in metal processing processes such as welding and cutting, the smoke generated can also be purified by this equipment.

4. Performance advantages

(1) High-efficiency dust removal: Small pulse filter cartridge dust collector has a high dust removal efficiency and can intercept micron-level dust to ensure the cleanliness of exhaust gas.

(2) Energy saving and environmental protection: The equipment adopts pulse jet technology, which has good dust cleaning effect, low energy consumption and meets environmental protection requirements.

(3) Strong stability: The dust collector is made of high-quality materials and advanced technology, has high stability and reliability, and can operate stably for a long time.

(4) Easy maintenance: The equipment has a simple structure and is easy to maintain, which reduces the maintenance cost of the enterprise.

5. Operation and Maintenance

When operating a small pulse filter cartridge dust collector, pay attention to the following points:

(1) Check the cleanliness of the filter cartridge regularly. If the filter cartridge is found to be blocked or damaged, it should be replaced in time.

(2) Maintain the normal working state of the pulse injection system and regularly check parameters such as air source pressure and injection frequency.

(3) Clean and maintain the dust collector regularly, including cleaning the ash hopper, checking seals, tightening bolts, etc.

(4) Strictly abide by operating procedures and safety precautions to ensure the safe operation of the equipment.

6. Future Development

With the continuous improvement of environmental protection requirements and the development of industrial production, small pulse filter cartridge dust collectors will face more challenges and opportunities. In the future, the equipment will develop in a more efficient, energy-saving and intelligent direction. For example, by introducing advanced sensor technology and Internet of Things technology, remote monitoring and intelligent control of dust collectors can be realized; by optimizing filter materials and structural design, the filtering performance and stability of dust collectors can be improved; by developing new cleaning technologies, energy consumption and emissions can be reduced.

In short, as a highly efficient and energy-saving dust removal equipment, the small pulse filter cartridge dust collector plays an important role in industrial production. With the continuous advancement of technology and the continuous expansion of application fields, this equipment will show a broader market prospect and development potential in the future.

If you want to learn more about our collector, please contact:

Yulia Zhang

Email: yuliazhang@jnhxgm.com

Phone/WhatsApp/Wechat: (86)19819766150