Pulse cartridge dust collector structure

Corporate News

2024-05-30 16:56:19

1、 Structure

This dust catcher is composed of six parts: box, ash hopper, ladder platform, bracket, pulse cleaning and ash discharge device.

2、 Working Principle

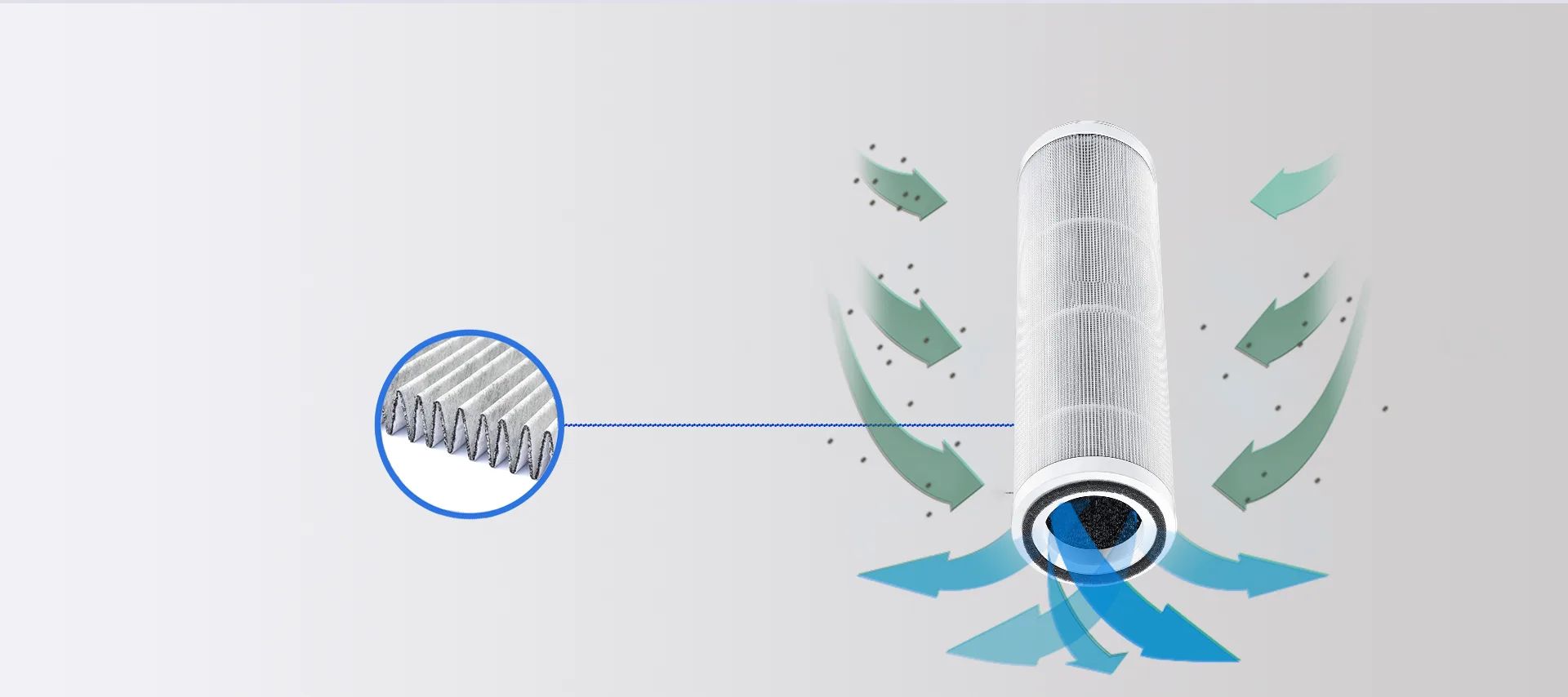

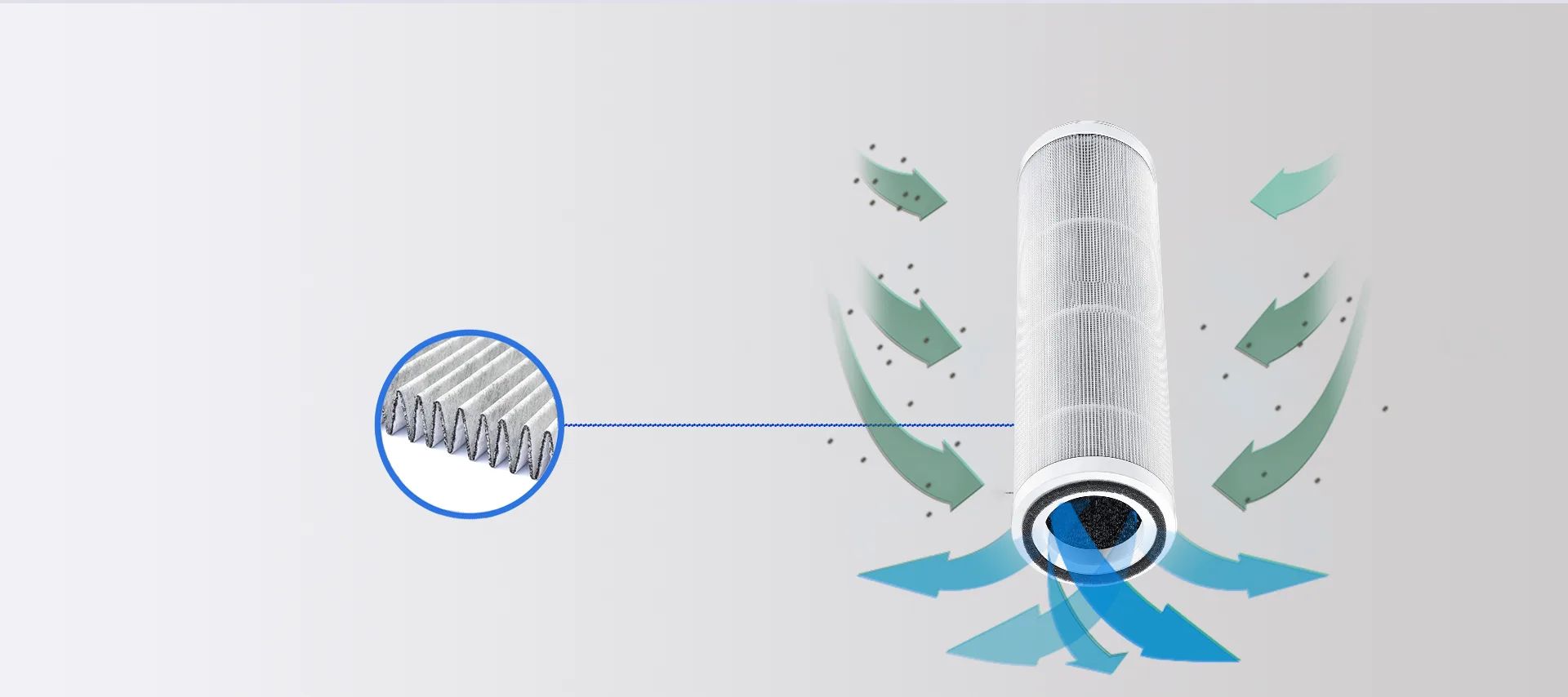

Under the action of the main fan of the system, the dusty gas enters into the air box at the bottom of the dust collector from the air inlet of the lower part of the dust collector for the pre-treatment of the dusty gas, and then enters into the dust removal chambers in the upper box from the bottom; the dust is adsorbed on the outer surface of the filter cartridge, and the clean gas after filtration enters into the clean gas chamber in the upper box through the filter cartridge and is collected and discharged to the air outlet.

As the filtration condition continues, the dust accumulated on the outer surface of the filter cartridge will be more and more, which will increase the operating resistance of the equipment accordingly, in order to ensure the normal operation of the system, the dust collector resistance limit should be maintained within the range of 1400~1600Pa. In order to ensure the normal operation of the system, the dust collector resistance I-limit should be maintained in the range of 1400-1600Pa, when it exceeds this limit, it should be automatically cleaned by PLC pulse automatic controller through a fixed Yang or timed instructions.

The cleaning process of cartridge dust collector is to cut off the net gas outlet channel of a certain room first, so that the airflow in the room is static, and then carry out the compressed air pulse blowing to clean up the dust, and then after a number of seconds of natural settlement, then open the net gas outlet channel of the room, which not only clears up the dust thoroughly, but also avoids the secondary adsorption of the powder generated by the spraying and cleaning of the cattle, and so the cycle of cleaning up the dust room by room.

This dust catcher is composed of six parts: box, ash hopper, ladder platform, bracket, pulse cleaning and ash discharge device.

2、 Working Principle

Under the action of the main fan of the system, the dusty gas enters into the air box at the bottom of the dust collector from the air inlet of the lower part of the dust collector for the pre-treatment of the dusty gas, and then enters into the dust removal chambers in the upper box from the bottom; the dust is adsorbed on the outer surface of the filter cartridge, and the clean gas after filtration enters into the clean gas chamber in the upper box through the filter cartridge and is collected and discharged to the air outlet.

As the filtration condition continues, the dust accumulated on the outer surface of the filter cartridge will be more and more, which will increase the operating resistance of the equipment accordingly, in order to ensure the normal operation of the system, the dust collector resistance limit should be maintained within the range of 1400~1600Pa. In order to ensure the normal operation of the system, the dust collector resistance I-limit should be maintained in the range of 1400-1600Pa, when it exceeds this limit, it should be automatically cleaned by PLC pulse automatic controller through a fixed Yang or timed instructions.

The cleaning process of cartridge dust collector is to cut off the net gas outlet channel of a certain room first, so that the airflow in the room is static, and then carry out the compressed air pulse blowing to clean up the dust, and then after a number of seconds of natural settlement, then open the net gas outlet channel of the room, which not only clears up the dust thoroughly, but also avoids the secondary adsorption of the powder generated by the spraying and cleaning of the cattle, and so the cycle of cleaning up the dust room by room.

![[Dust Removal Case] Plate Welding Dust Removal Solution for a State-owned Coal Mine Machinery Comp](/d/file/p/2024/10-28/fa90a7026c233450e7f014c8eb9d79c5.png)